建議您使用以下瀏覽器觀看本網站,

以獲得最佳瀏覽效果。

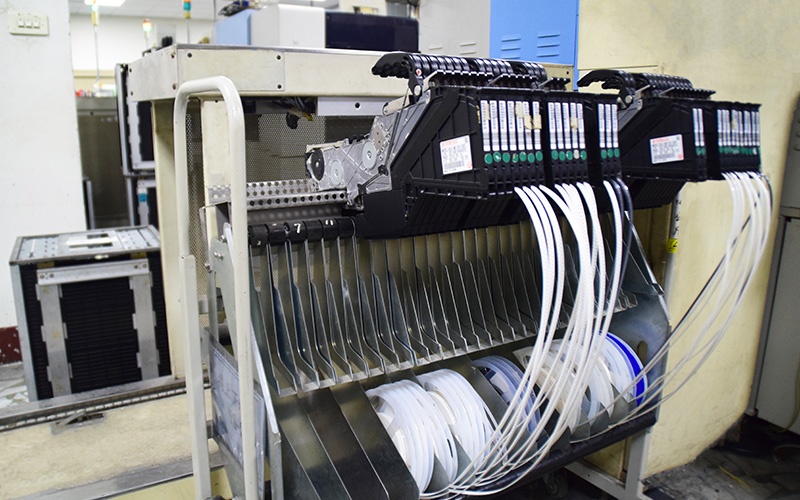

SMT Manufacturing Process

Yi-Tong is equipped with four SMT production lines and AOI to control the production quality. Well-trained inspectors for the additional inspection to ensure the high quality of manufacturing.

-

A Line : DIC LOADER+YAMAHA 100XG+YAMAHA 100X+BTU PYRAMAX 98+DER PAN UNLOADER

-

B Line : SIACIN LOADER+YAMAHA 100X+YAMAHA 100X+VITROHICS XPM1020

-

C Line : SUNG SHIEH LOADER+YAMAHA YS24+YAMAHA 100X+BTU PYRAMAX 98+DER PAN UNLOADER

-

D Line : YAMAHA 100II

SMT Production Equipment:

-

Line A : Mounting speed 20000Pcs/1hr and measures 50mm-400mm wide; applicable for components >RC0201, IC 0.4Pitch, and BGA.

-

Line B : Mounting speed 20000Pcs/1hr and measures 50mm-400mm wide, The length of the board can be up to 600mm.; applicable for components >RC0201, IC 0.4Pitch, and BGA.

-

Line C : Mounting speed 30000Pcs/1hr and measures 50mm-400mm wide; applicable for components >RC0201, IC 0.4Pitch, and BGA.

-

Line D : Mainly used for sample and trial productions, and measures 50mm-350mm wide; applicable for components >RC0402, IC 0.4Pitch, and BGA.

Daily Production Capacity:

-

Solder paste printer : Capable of printing >RC 0402, IC 0.4mmPitch and Micro BGA.

-

YAMAHA YV100D automated robot dispenser : Capable of dispensing >RC 0603; suitable for tin and plastic processes and provides visual effect with only 0.07mm deviation.

SMT Manufacturing Process

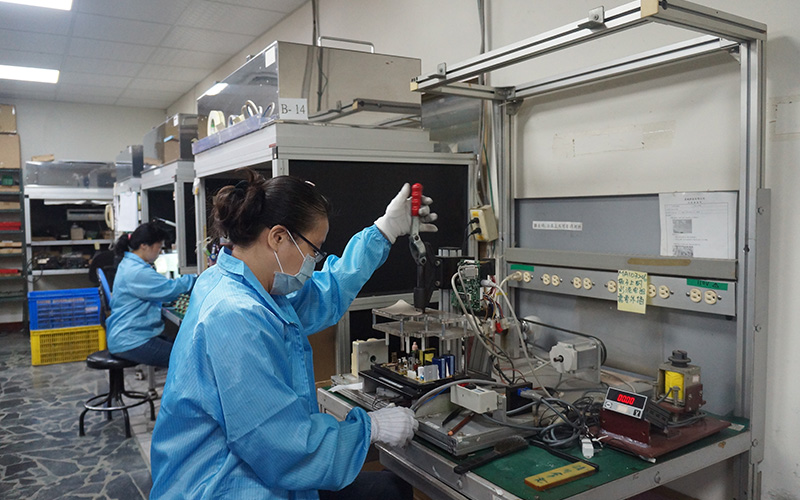

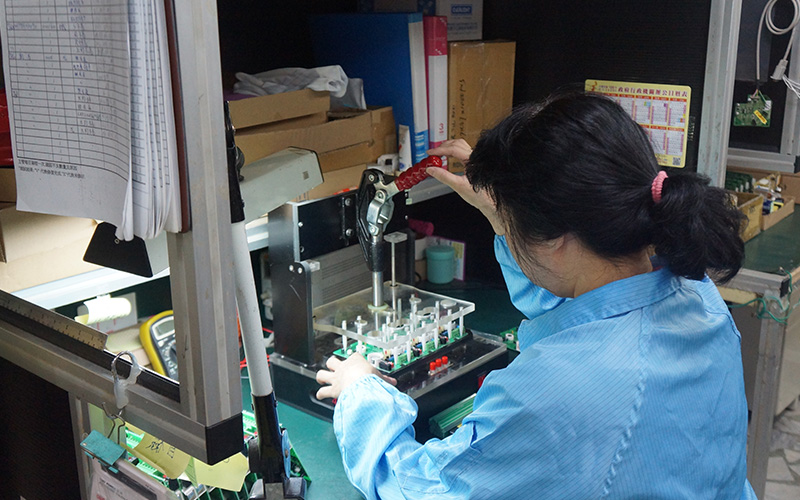

DIP Manufacturing Process

Yi-Tong has one DIP production line including insertions, corrections, manual welding and lead-free wave soldering etc. This production line is also equipped with machines for constant temperature iron soldering and dispensers to produce a maximum PCB size of L350mm*W400mm.

Besides, there are more advanced equipment such as PCB auto-cut machines, manual-insertion lines, repair welding lines, assembly lines, visual inspection, ICT auto-inspection, manual foot cutters, auto foot cutters, etc.

In addition, in order to solve labor shortage and cost, we also import automatic soldering machines, automatic lock screw machines, and Automatic dispensing machine of Yushun Technology. They already prove the enhancement of quality and efficiency except cost.

DIP Manufacturing Process

Automatic Soldering Machines :

- We can program the precise coordinates of the welding spots. It supports spot welding, drag soldering and various welding requirements.

- The quickly heating up and cooling down function of high-power core meet the requirements most products.

- We can locate next welding target while another is welding. It will significantly save the fixture change time.

Automatic lock screw machines :

The machines remain better efficiency and quality if compared to the general traditional hand-held electric screwdriver. It can automatically inspect the screw height to ensure there is no tilt and no over height after locks. The built-in smart inspection functions will finish intelligent check such as missing , heights, strips etc. It also supports different heights of locks. The torque set function will prevent loose lock.

Automated dispensing machine :

Automated dispensing machines can provide high efficiency, productivity and consistent quality which seems impossible if hand-held.

Two working platforms work simultaneously which take turns to finish dispensing. The high precision reliability is always proved. It also supports many functions such as constant positions and quantity production.

Random points, lines, planes, arcs and other irregular curves can be processed with continuous dispensing. Triaxial linear interpolations, triaxial circular interpolations, and elliptic arcs are also supported.

Testing, assembling process and abilities for final products

We are equipped with comprehensive assembly lines for final products, which meets the test requirements of customers in the production process, and equipped with various functional test stations.

Our SMT and DIP processes apply AOI and ICT inspection equipment to achieve clients’ expectations for product qualities.

Test process